Scott Miyako – makes traditional straight razors

Proponents of sustainability are in the right place in Portland, Oregon. This is where the autodidact and manufacturer of top-notch traditional straight razors Scott Miyako lives. We visited Scott, who wears Birkenstocks out of conviction, and spoke to him about quality and sustainability. And learned what makes for an excellent shave ...

Statistically speaking, the disposable razor blade is very popular – it rides high on the list of shoplifted items, with one in six packs being stolen. This is hardly surprising considering the high prices that the manufacturers demand compared with production costs per blade of just a few cents. This kind of unnecessary moneymaking was something that bothered Scott Miyako of Portland, too. He was also unhappy with his own consumer behavior – it irked him as an eco-friendly person that he was constantly throwing away used disposable razors so he looked around for a sustainable and optimum alternative.

The birth of a business idea

At that time, the qualified mechanical engineer was running a shop in Los Angeles selling guitar amplifiers he made himself. Out of interest, he began to collect and restore traditional razor blades, and eventually went on to make his first own straight razor. Satisfied with his first attempt, he began to make others for friends and family. He began to enjoy the whole process and also found it much more agreeable than putting together those complicated amplifiers.

Scott believed in his business idea and was prepared to invest everything he had in it – he sold his business and his three classic cars, and moved to Portland together with his girlfriend Alex to henceforth produce razors. And it worked out. “People were interested in what we were doing and the first orders soon came flooding in,” relates Scott enthusiastically.

Working up to top quality step by step

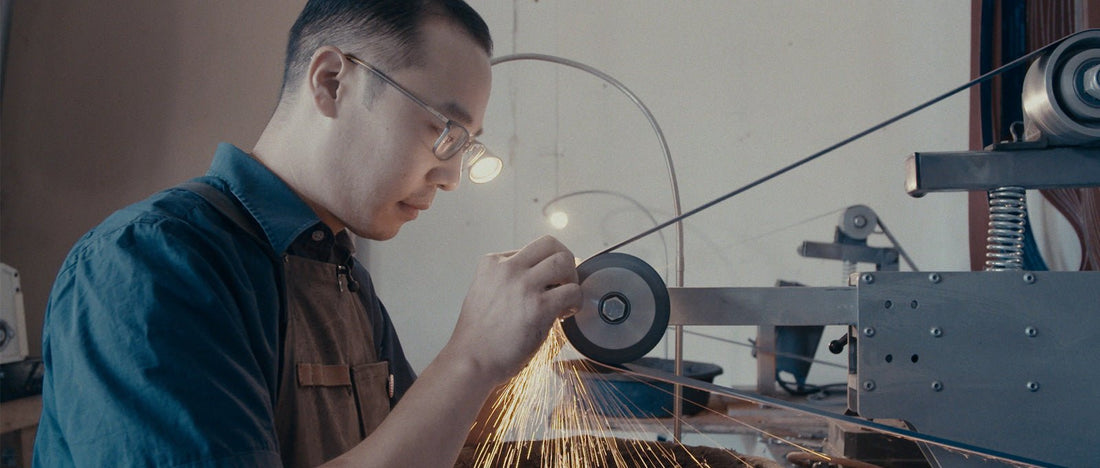

The Portland Razor Company has now been in existence for a good four years. It manufactures nine different straight razor models ranging in price from 150 to 300 dollars. Alex handles the marketing, while Scott and his employee Hunter make the razors – around 100 a month. Scott explains the importance of concentration for this handcraftsmanship: “There are countless manufacturing steps, including water jetting, hollow grinding, filing, heat treatment, buffing, polishing, sharpening and, finally, assembly. And any one of them can ruin the razor.” He wants to produce things that are made to last so quality is his top priority. “And that involves the craftsmen putting 100% of their energy into their work!” he says.

Made to last

Although Scott’s razors might initially seem expensive, on balance they are a worthy investment because they are made to last a lifetime. And Scott brushes off the question as to whether he isn’t simply jumping on the current retro trend bandwagon: “We’re not looking to bring back the old-fashioned method simply for the sake of it – we really believe that straight razors are the best tool for a fine shave and they’re really the best alternative for the aspect of sustainability.”

Nothing about BIRKENSTOCKs that could be improved

Scott is very quality-conscious, and this is one of the reasons why he has been wearing Birkenstocks for years: “I grew up with these sandals. I had problems with my feet as a kid and the doctor recommended wearing Birkenstocks,” he explains.

For Scott, there’s nothing about Birkenstocks that could be improved. He associates the name with nothing but quality and very good customer service. His girlfriend Alex, who likewise likes to wear Birkenstocks, doesn’t entirely agree: “I do have a suggestion for how they could be improved. Add heels – then I’d be a little taller!”

For more information: http://www.portlandrazorco.com/

*All photos and content are form the BIRKENSTOCK USA site.